Envirohood wall mount are installed on the wall inspection of the wall structure should be check before installation.

The Certified, Proprietary, Type 7 Envirohood will be as follows:

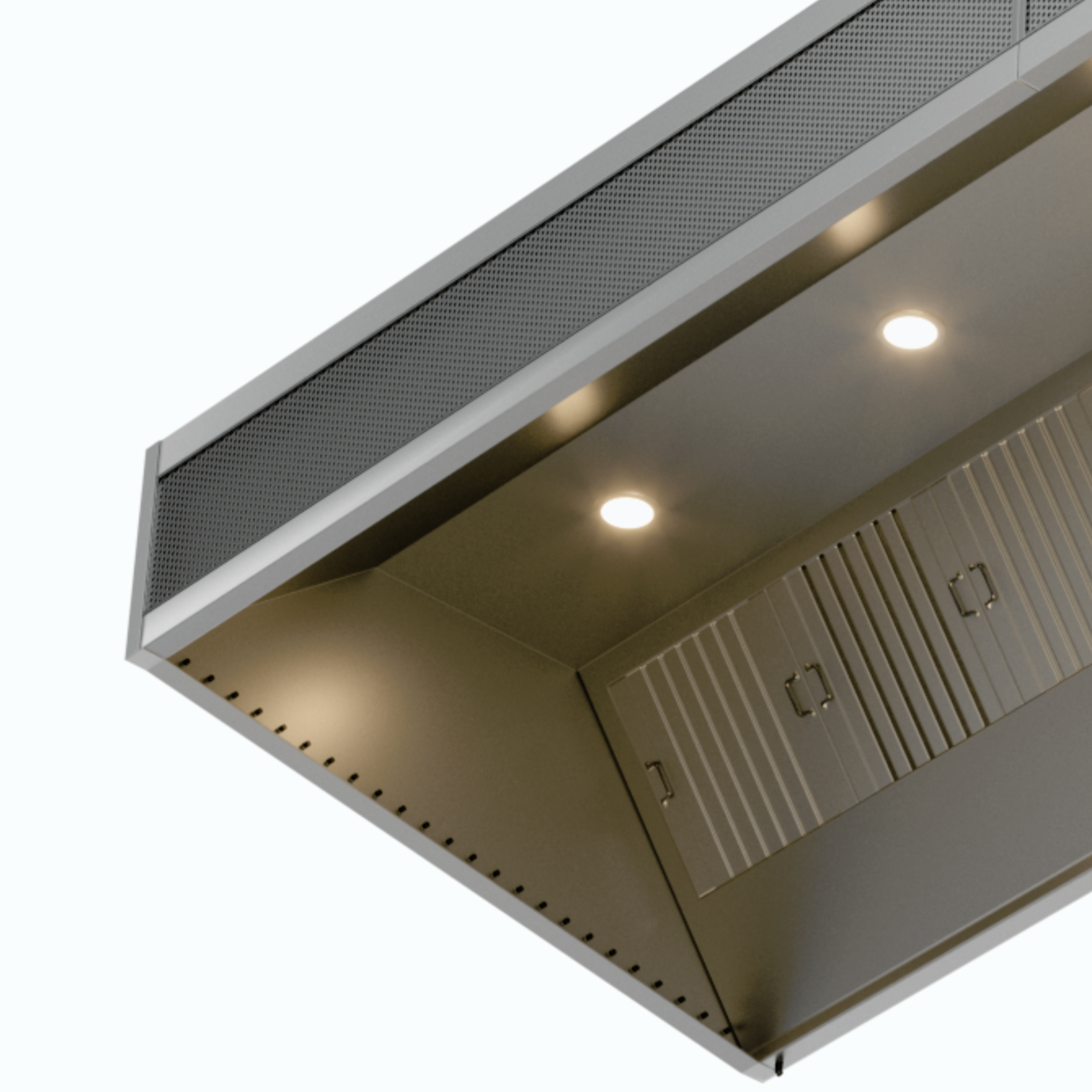

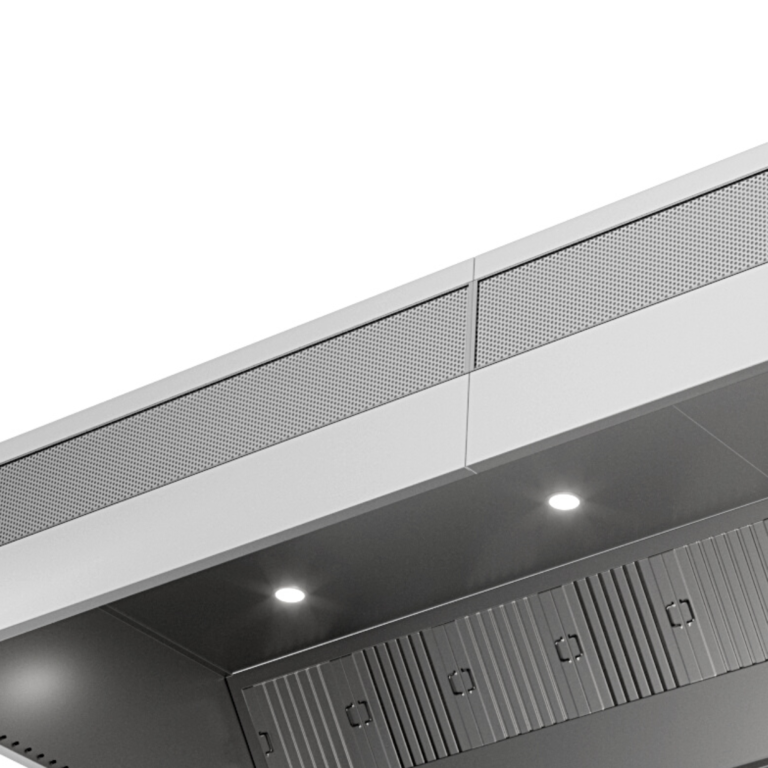

The hood will be fully constructed from 1.2mm 304 Grade Stainless Steel and polished to a No 4 finish. Non exposed interior sections (including roof) of the Envirohood shall also be manufactured from Stainless Steel (no Galvanised Steel allowed).

For longer continuous length hoods, the Envirohood shall be be manufactured in sections.

The Envirohood shall have Brushed Stainless Steel,IP44 rated, Flush Mounted LED Lights capable of being interchangeable from Cool White, Warm White or Daylight.

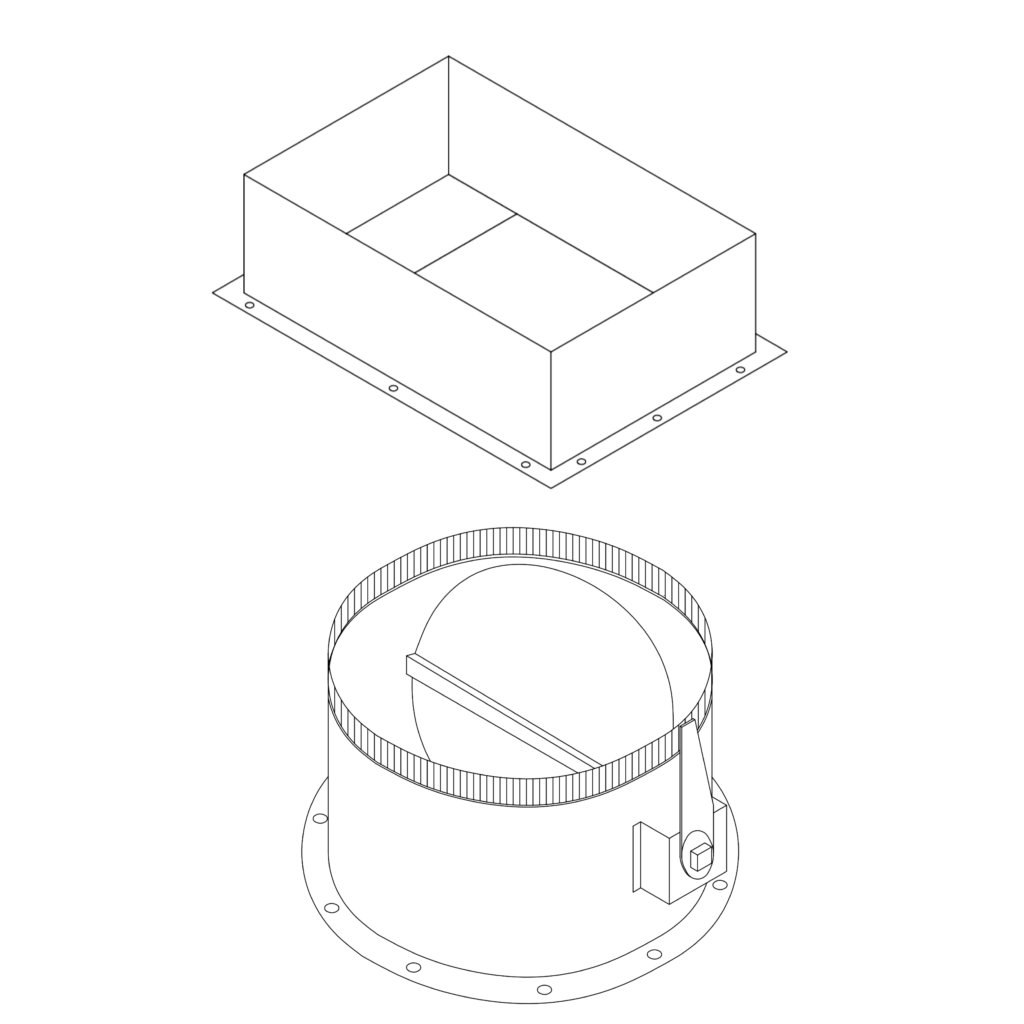

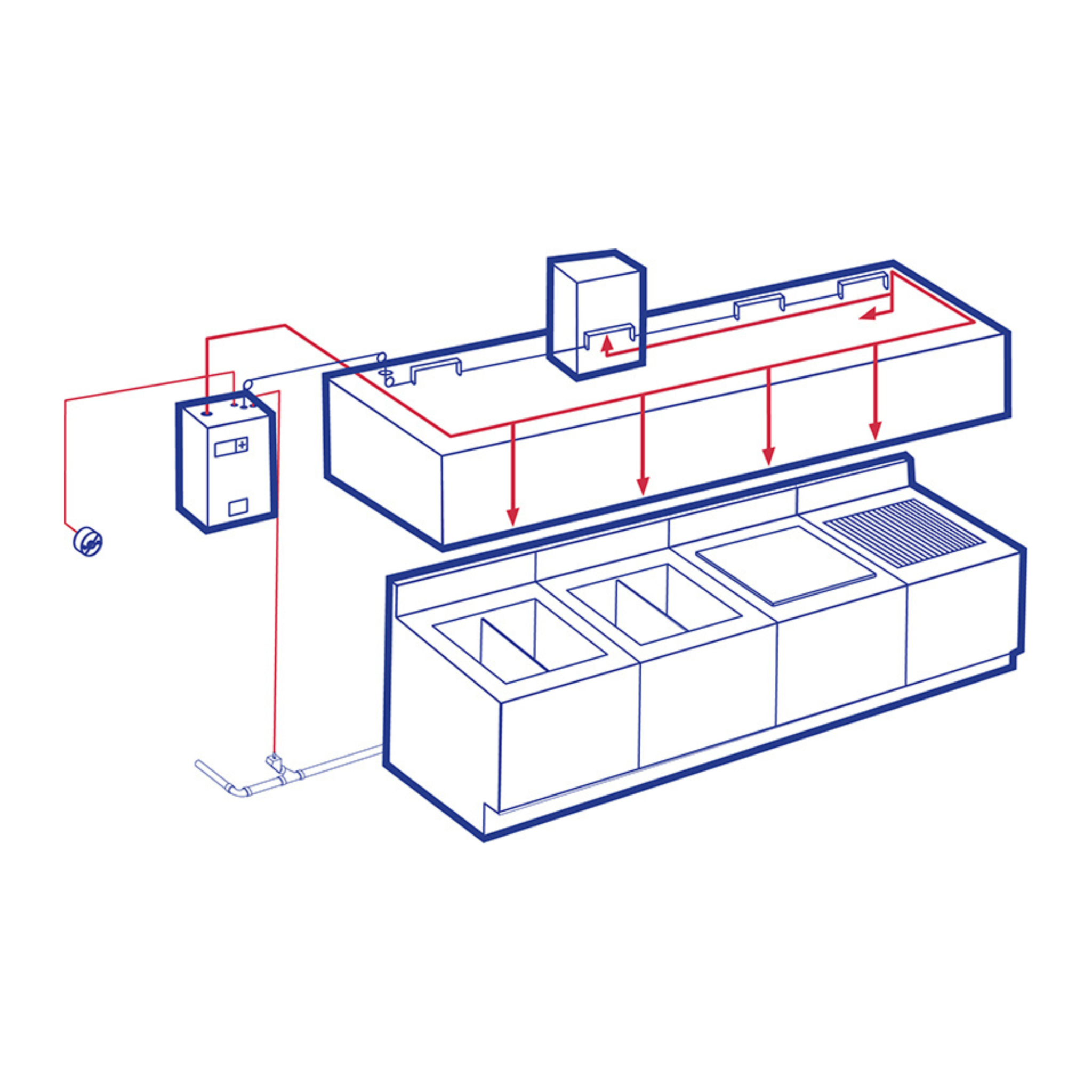

Exhaust air spigots and Make Up air spigots are to be located on the top of the hood.

Make Up air spigots are to be 250 mm diameter and connected via flexible ducts to supply a minimum of 80% of the exhausted air (as Make Up air) to the conditioned space as per the requirements of AS 1668.2

The Stainless Steel perforated front face Make Up air panel shall be removable without the need of tools (no screws).

Air Balancing will be achieved by built-in double skin slide dampers, accessible from within the hood, for the Exhaust air and pivot volume control dampers in the spigots for the Supply air.

There will be a gutter of a minimum size of 70mm wide by 25mm high on all four sides of the hood for oil and grease collection. These shall be fitted with removable 40 diameter drain plugs, welded and polished, on the rear gutter for oil collection.

The built in Air Curtain is to be independently pressurised with an integral, 10 speed, centrifugal jet fan/s (factory set). The Air Curtain delivers the air via small, engineered orifices around the inside perimeter of the hood to ensure the capture and containment efficiencies are met.

Filtration is achieved through either Certified CSIRO 1530.1 Stainless Steel Honeycomb Filters or UL Approved Stainless Steel baffle filters.

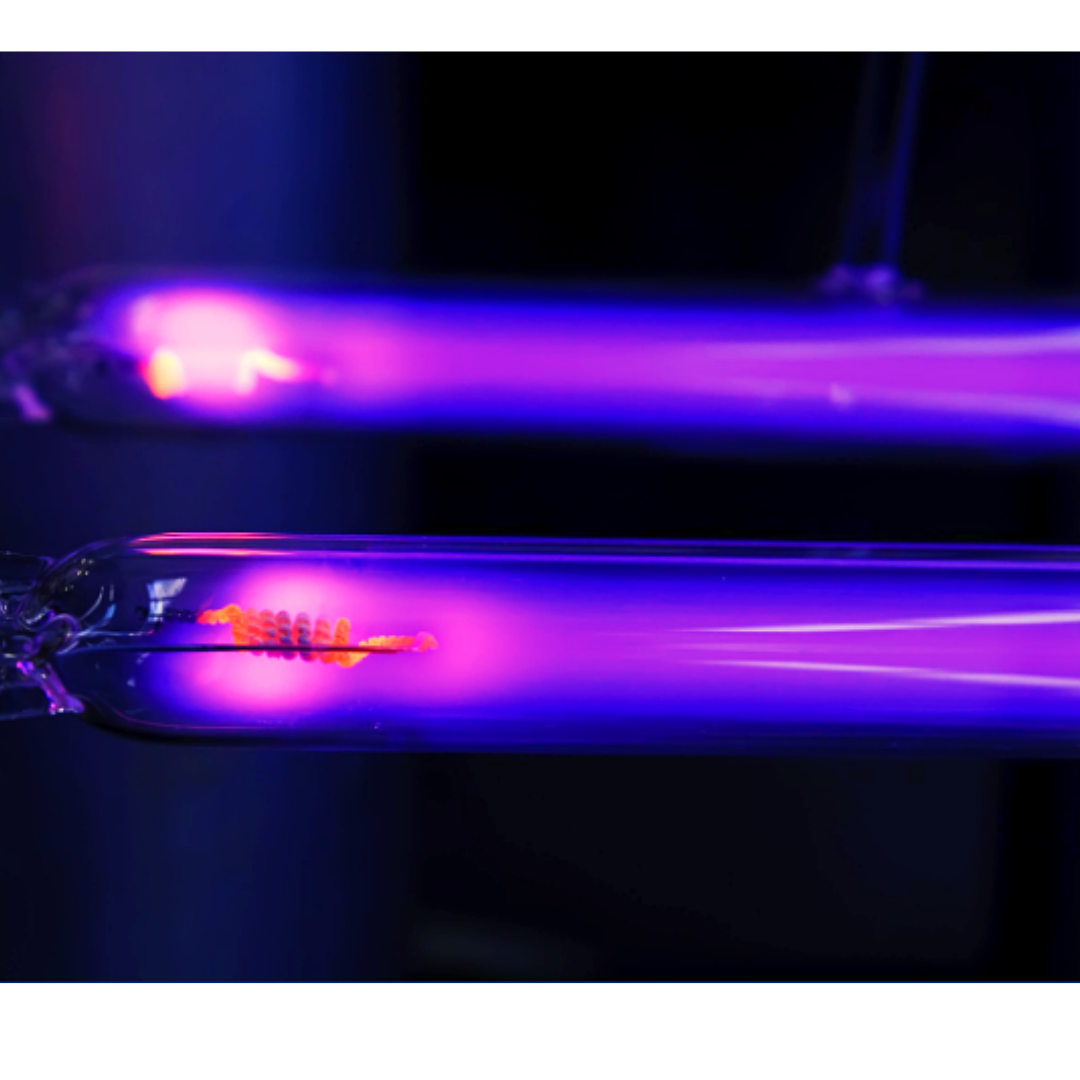

All Envirohood models available with integrated UV technology to remove grease and odours in the kitchen exhaust system.

The ansul fire suppression system can be integrated in all Envirohood models for fire protection.

All Engineering and Compliance Certification is to be independently certified by Global Mark Pty Ltd.